![[Banner Image]](images/PurgexBar.gif)

![[Home]](images/bhome.gif)

![[What's New]](images/bnews.gif)

![[Products & Services]](images/bprdsrv.gif)

![[Contents]](images/btoc.gif)

![[Feedback]](images/bfeed.gif)

![[Search]](images/bsrch.gif)

Please visit their Web Page

Please visit their Web Page

Key Benefits

-

![[Bullet]](images/bullet.gif) Purges

many shots sooner than other compounds

Purges

many shots sooner than other compounds

-

![[Bullet]](images/bullet.gif) Good for

maintaining extruders and cleaning out carbon

Good for

maintaining extruders and cleaning out carbon

-

![[Bullet]](images/bullet.gif) Less expensive

than other compounds

Less expensive

than other compounds

-

![[Bullet]](images/bullet.gif) Follow purging

steps like this:

Follow purging

steps like this:

-

- Disengage barrel from manifold / hot runner

-

- Empty hopper of resin

-

- Empty barrel by cycling machine 2 or 3 times w/ max shot

size

-

- Extrude remaining resin until screw can be seen

-

- Fill hopper

with enough Purgex blend to fill barrel plus a little extra

-

- Run shots until purge is at nozzle

-

- Soak 5-8 min. (any longer than this is for the most part a waste of time)

-

- Cycle machine with NORMAL shot size

-

- If clean white extrudite is not obtained, repeat process

(first time this is normal)

-

- Engage barrel nozzle into manifold / hot runner

-

- If present, turn off coolant water on nozzle heater inside

manifold

-

- Run 1/3 short shot

-

- Soak for 5 minutes

-

- Repeat until clean purge compound appears

-

- Chase with new resin

-

- Turn water back on

![[Bullet]](images/bullet.gif) Sold in

5 lbs pkgs,10 lbs pkgs,100 lbs barrels, or 1000 lbs gaylords

Sold in

5 lbs pkgs,10 lbs pkgs,100 lbs barrels, or 1000 lbs gaylords

-

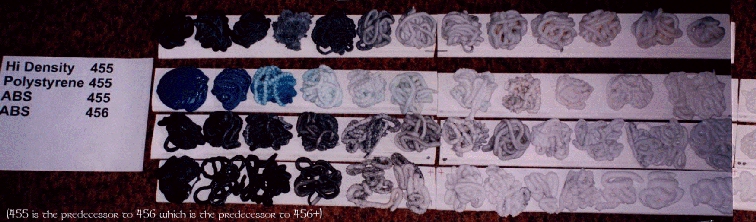

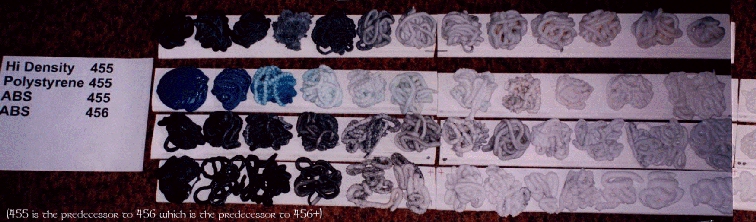

![[Bullet]](images/bullet.gif) Part #PURGEX456+

for lower temperatures (280-500°F)

Part #PURGEX456+

for lower temperatures (280-500°F)

-

![[Bullet]](images/bullet.gif) Part #PURGEX457+

for lower temperatures (280-500°F) with Fiberglass scrubbing

Part #PURGEX457+

for lower temperatures (280-500°F) with Fiberglass scrubbing

-

![[Bullet]](images/bullet.gif) Part

#PURGEX3056+

for higher temperatures (280-600°F)

Part

#PURGEX3056+

for higher temperatures (280-600°F)

-

![[Bullet]](images/bullet.gif) Part

#PURGEX3057+

for higher temperatures (280-600°F) with Fiberglass scrubbing

Part

#PURGEX3057+

for higher temperatures (280-600°F) with Fiberglass scrubbing

-

![[Bullet]](images/bullet.gif) Part #PURGEX4000

for all temperatures (280-600°F)

Part #PURGEX4000

for all temperatures (280-600°F)

Click Here to see MSDS sheets

![[Dividing Line Image]](images/div.gif)

![[Home]](images/bhome.gif)

![[What's New]](images/bnews.gif)

![[Products & Services]](images/bprdsrv.gif)

![[Contents]](images/btoc.gif)

![[Feedback]](images/bfeed.gif)

![[Search]](images/bsrch.gif)

Send mail to acelliott@pyromatic.com

with questions or comments about this web site.

Last modified: August 30, 2004

![[Home]](images/bhome.gif)

![[What's New]](images/bnews.gif)

![[Products & Services]](images/bprdsrv.gif)

![[Contents]](images/btoc.gif)

![[Feedback]](images/bfeed.gif)

![[Search]](images/bsrch.gif)

![[Banner Image]](images/PurgexBar.gif)

![]()